Meshes for Industrial Materials

Trial weaving (prototyping) service

industrial-applicationsWe can perform trial weaving (prototyping) and simulations of mesh according to customer requirements.

We offer trial weaving (prototyping) services in accordance with customer requests by utilizing the design and weaving technologies we have cultivated over many years in a variety of fields. We can also produce mesh with specifications that are not included in our product lineup, so please consult with us.

We will confirm your requests and required characteristics at the meeting and propose mesh specifications and design.

In addition, by clarifying issues from the trial weaving (prototyping) stage with a view to mass production, we are able to shorten the lead time for start-up.

Features

Application examples

Product specifications

| materials |

|---|

| Mesh count |

| Wire diameter |

| Application examples |

| Material of mesh |

| Processing methods |

| Target material |

| Features |

| Applications |

| Resin materials |

Comparison of properties

| Tensil strength |

|---|

| emulsion adhesion |

| antistatic capability |

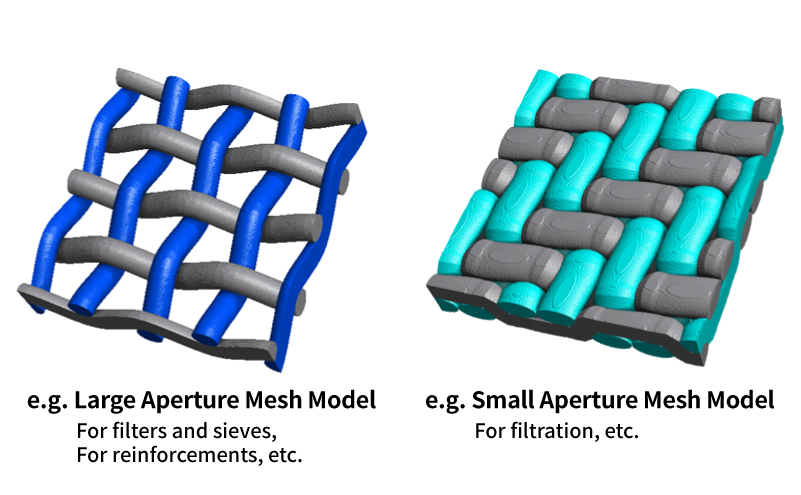

We also create mesh models and simulate mesh properties utilizing simulation software.

Design accuracy can be improved by simulation-based prediction in the design phase before trial weaving.

It also reduces the time required for trial weaving, evaluation, etc., and enables more timely product development.

[Examples of characteristics that can be simulated]

Mesh shape, thickness, porosity, air permeability, pressure loss, electromagnetic characteristics, etc.

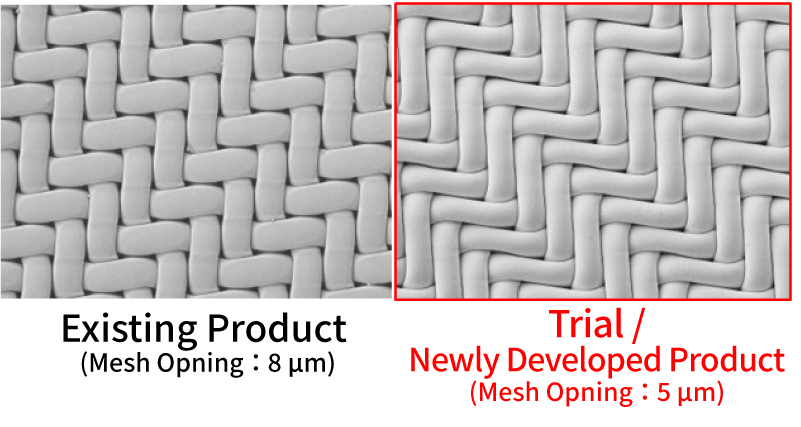

Application: Sieve mesh for sifting finer powder. Mesh with smaller openings that was not available in the existing lineup.

Based on customer requests, NBC Meshtec proposed designs for weave structure and wire diameter, and developed mesh with smaller openings than conventional products using its weaving and processing technologies. The newly developed product achieves 5 µm mesh openings.

Thus, non-standard products are also available for consideration.

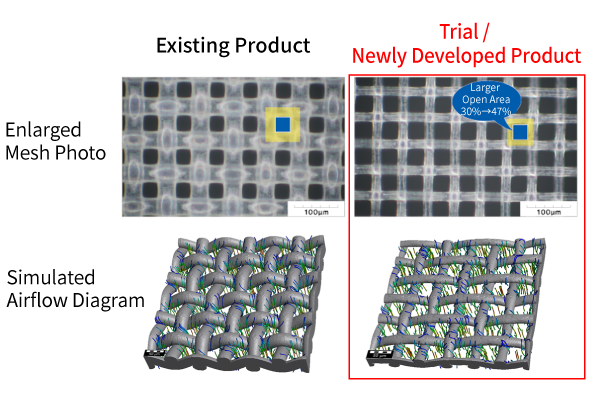

Application: Filter with improved filtration efficiency. Use of finer threads increases the open ratio to improve efficiency.

By using finer threads than before, only the open ratio has been increased without changing the mesh opening.

This resulted in an increased overall airflow rate and improved filtration efficiency.

In addition, by simulating airflow during the design phase, we were able to confirm the validity of the design prior to trial weaving.

The ability to predict the characteristic values of the mesh at the stage before actual weaving can shorten product development schedules.

Application: Daily commodities: “Want to change the current mesh material.” Collaboration with the thread manufacturer from the thread development stage has realized a mesh with fine polyolefin threads.

This is an example of new design and trial weaving for a customer who had been using nylon mesh and wanted to change the mesh material to polypropylene.

The existing lineup of polypropylene mesh mostly has thick wire diameters, but the customer requested a mesh with a finer wire diameter, so we worked with the thread manufacturer to develop and procure finer threads.

Related documents

Did you find what you were looking for?

If you have any questions or concerns about industrial material mesh, please feel free to contact NBC Meshtec.

We propose appropriate meshes and processing technologies to give shape to our customers’ wishes.